|

|

|

|

STRAIGHT LADDER |

|

|

90° HORIZONTAL BEND |

|

|

30°VERTICAL BEND INSIDE |

|

|

90°VERTICAL BEND OUTSIDE |

|

|

90°VERTICAL BEND INSIDE |

|

|

UNIQUAL TEE |

|

|

CROSS |

|

|

REDUCER RIGHT |

|

|

REDUCER COUPLER PLATE |

|

|

PARTITION PLATE |

|

|

SUPPORTING BRACKET |

|

|

COUPLER PLATE |

|

|

EARTH BONDING STRAP |

|

|

BEAM CLAMP |

|

|

CEILING BRACKET |

|

|

HOLD DOWN CLIP (‘S’ TYPE) |

|

|

ANGLE LADDER STRAIGHT |

|

|

|

STRAIGHT TRAY |

|

|

|

90° HORIZONTAL BEND |

|

COVER |

|

|

TEE |

|

HANGER ROD |

|

|

‘C’ TYPE CHANNEL SUPPORT |

|

|

90° VERTICAL BENDINSIDE / OUTSIDE |

|

|

EYE BOLT |

|

|

|

|

EYE BOLT NUT |

|

|

REDUCER STRAIGHT |

|

|

ANGLE SUPPORT |

|

|

COUPLER PLATE |

|

|

PIPE CLAMP |

|

|

OVERHEAD HANGER |

|

|

|

|

|

|

|

|

|

|

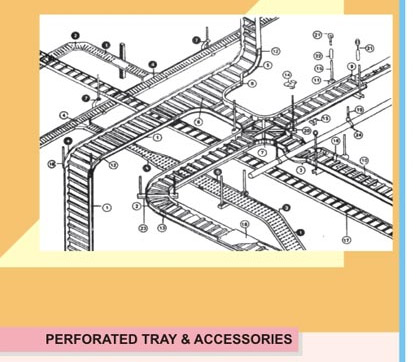

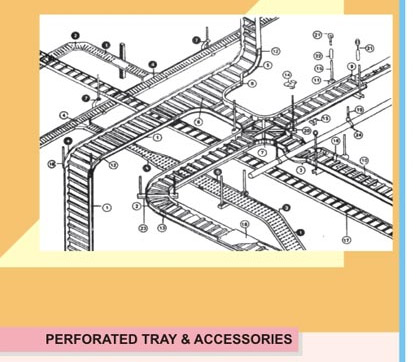

PERFORATED CABLE TRAYS MS ANDALUMINIUM / POWDER COATING / SS |

|

|

|

|

|

Perforated cable trays are fabricated out of single

sheet steel conforming to IS 1079 or IS 2062 in various

thickness of 1.6 mm, 2.0 mm, 2.5 mm and 3 mm.

Perforated cable trays are available in standard widths

of 50 mm, 100 mm, 150 mm, 300 mm, 450 mm and 600

mm and in standard length of 2500 mm.If other than the above mentioned widths are requires the trays can be fabricated as per the specification of

customer / customer consultants.Aluminium perforated cable trays are fabricated as similar to MS perforated cable trays and available 50 mm to600 mm width or per requirement. |

|

|

| PERFORATED CABLE TRAYS SPECIFICATIONS ( MS & ALUMINIUM / POWDER COATING / SS ) |

|

| 1. Standard length |

– |

2.5 mtrs. |

| 2. Perforations |

– |

10 * 20 mm widthwise 10 mm gap. |

| 3. Tray width (W) |

– |

50 mm, 75 mm, 100 mm, 150 mm, 200 mm, 300 mm, 450 mm, 600 mm, or any size as per

requirement. |

| 4. Tray Height (H) |

– |

20 mm, 25 mm, 40 mm, 50 mm, 75 mm, 100 mm or any height as per requirement. |

| 5. Tray Collar (C) |

– |

15 mm, 20 mm, 25 mm. |

| 6. Tray Thickness (TH) |

– |

1.6 mm, 2 mm, 2.5 mm, 3 mm |

| 7. Types of materials |

– |

MS/ Aluminium. |

| 8. Finish |

– |

Hot dip galvanized, epoxy coated and enamel painted. |

|

|

|

|

|

| LADDER TYPE CABLE TRAY |

|

| Ladder the cable trays are fabricated out of steel sheets conforming to usIS 1079 : IS 2062 with a thickness of 1.6 mm, 2.0 mm, 2.5 mm, and 3 mm.

RAW MATERIAL :

Steel sheets are procured for reputed local suppliers of SAIL and ESSAR

STEEL etc.

All the cable trays are of standard length of 2500 mm of various widths

minium being 150 mm wide and maximum 1000 mm wide. Slotted rung are

welded to the side runners every 250 mm interval. At both the ends of the cable

trays four circulars holes are provided for connecting the adjacent cable tray or

accessories / by coupler plates. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LADDER TYPE CABLE TRAY SPECIFICATIONS :

|

1. Standard Length (L) –

|

2.5 mtrs.

|

|

2. Runner Height (H) –

|

50 mm, 60 mm, 75 mm, 100 mm, 120 mm.

|

|

3. Runner Collar (C) –

|

15 mm, 20 mm, 25 mm, 30 mm.

|

|

4. Welding –

|

are welding is done by qualified welders and during the process of welding it isensured that material / fabrication electrode material etc., weld preparation weldingcurrent, voltage etc. accurately maintained and all welds are free from defect like

blowholes, cracks under cutting and slag inclusion. Welds are of the specified size are

in accordances with IS 816-1969.

Qualified welders are only employed after training.

|

|

|